COVID-19 changed how retailers operates. In particular, it pushed consumers further online and slowed supply chains. The last point remains a huge focus, as hiccups in the supply chain pose large risks for retailers.

Of course, a pandemic is not the only way a supply chain can be impacted. It could be extreme weather, transport route blockages, and much more. All of this shows how important it is to improve supply chain resilience.

Here are three methods to improve supply chain resilience.

AI Technology for Supply Chain Forecasting

One of the most critical steps of supply chain management is forecasting potential difficulties. Trying to adapt to inventory shortages as they come is a quick path to a losing battle, especially with a projected 22% global growth of online sales by 2025. This puts retailers in a position of needing to keep up with the rapid growth, which can be difficult using primarily human operations.

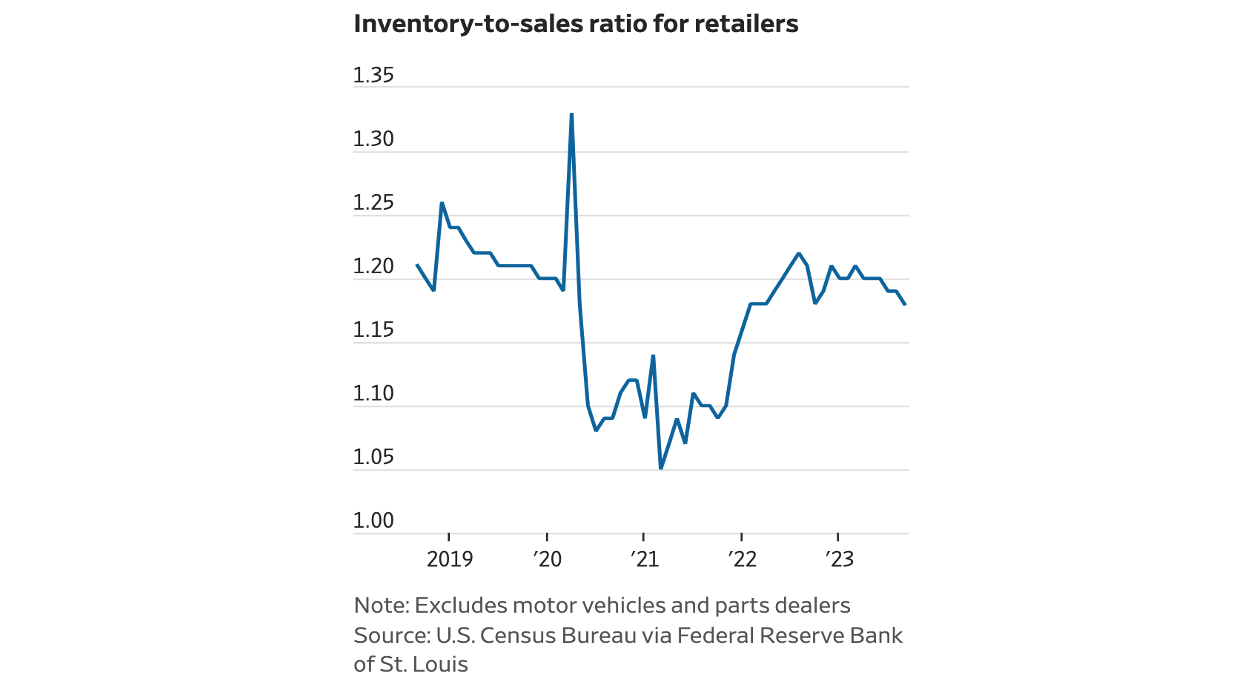

Retailer inventories have now normalized to pre-pandemic levels after several years of supply chain disruptions.

Let’s take a look at an example. Retailer “A” generally has a steady supply of their products coming in for the rate that they sell them. All of a sudden, there is an uptick in sales, leading to a shortage of inventory. If the product is complex, it will likely take some time to manufacture. This means that “A” could potentially run out of inventory because they had not considered the time frame it would take to get a rush order filled.

This is where the era of artificial intelligence (AI) can be a massive boon for retailers, whether big or small. Of course, AI has been used in many capacities over the past couple of decades, but it has significantly evolved. It is hard not to see articles about AI being used in a new way across the web. And this is only expected to grow, with AI projected to contribute up to $15.7 trillion to the global economy in 2030.

AI can become an incredible tool for retailers looking for more automated forecasting of supply chain management. It can monitor the entire chain, collect data, and predict shifts in demand to adjust inventory before a shortage or overstock.

Transparency Along Every Part of the Supply Chain Definition

Many moving parts are included as part of the supply chain definition as a whole. Simply put, the network of people and businesses takes raw materials to the end products for the consumer.

Some businesses may feel that their only concern is the portion from where their product is made and then delivered to them. While this will be their primary area, they must also consider difficulties affecting each portion of the chain. According to McKinsey, there are five areas where supply chain vulnerabilities often show up:

- Planning and Supplier Networks

- Transportation and Logistics Systems

- Financial Resiliency

- Product Complexity

- Organizational Maturity

Many retailers probably focus on the manufacturing and transportation portions, as they are the areas of direct communication. However, neglecting the other areas can leave a company stranded when a delay or issue is further up the line.

Situations like these can have a steep price, as research suggests a supply chain disruption of a month or longer can cost an organization 45% of a year’s profits over a decade.

A comprehensive view of the supply chain allows retailers to see various points of interconnectivity and where vulnerabilities could exist between areas.

Flexibility in Supply Chain Logistics

A key part of supply chain resilience is maintaining flexibility. This means adapting and scaling up or down depending on the current market. Unfortunately, 49% of retailers lack flexibility during peak seasons, and 37% cannot scale up or down as needed.

Say a retailer typically doesn’t have any problems in the supply chain. All they have to do is place the order and check on the transportation for the time it will arrive. All is good to go, until their manufacturer has a hold up due to broken down machinery, or transportation is slowed. All of a sudden, chaos ensues because they have never had to find alternate means to fulfill these duties.

Addressing this situation can take a multi-pronged approach using technology and transparency, as mentioned above, and diversification. In other words, having multiple suppliers and transport options in case of a manufacturing shortage or delay.

The past several years have shown how easy it is for port congestion or freight delays to put supply chains in danger. For example, the Suez Canal blockage of 2021 held back an estimated $9.6 billion of trade. Companies can best combat these issues by building diversity in their shipping and warehousing lines. In the event of a disruption, retailers should hold onto options for re-directing inventory if a specific route or warehouse is out of commission.

What supply chain strategies are you focused on for the next year?